Relentless cost and output optimization procedures force many facility operators to reduce staff. Cutting cost on maintenance can bear however considerable risks unless state-of-the-art technologies are employed. While our roots are in instrument manufacturing, our responsibilities naturally extend to ensuring the correct instrument installation and measurement performance. We join forces with mechanical engineers to offer you the best-suited solutions when and where you need them.

Preserve the integrity of the water-steam circuit

The constant contact of water and steam with pipes in boilers, heat recovery steam generators (HRSGs), condensers and turbine blades can cause equipment deposits/scaling and corrosion, affecting the availability of the water-steam system.

Our expertise in the field

We offer a standardized and modular steam/water quality control solution (SWAS) which enables the measurement of critical parameters like specific and cationic conductivity, pH, silica dissolved oxygen (DO) and sodium.

- Panels are equipped with cutting-edge and cost-effective sensor/transmitter technology (Memosens/Liquiline)

- Engineering services and supply of sampling & analysis systems for the water-steam cycle

- Worldwide services to EPC contractors and power plant operators

Avoid any legal disputes on steam measurement

When a new power plant does not produce the thermal efficiency specified in the contract, the boiler supplier and the turbine manufacturer may disagree about the amount of steam supplied. Thus, the use of an agreed standard (ISO 5167) and a dp-flow primary element, e.g. orifice plate, venturi tube and nozzle, ensure that 3rd party experts can easily validate the meter, the set-up and the design calculations for the steam volume or mass.

Our expertise in the field

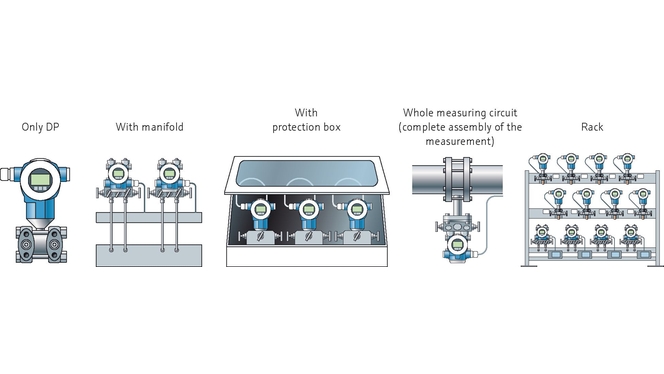

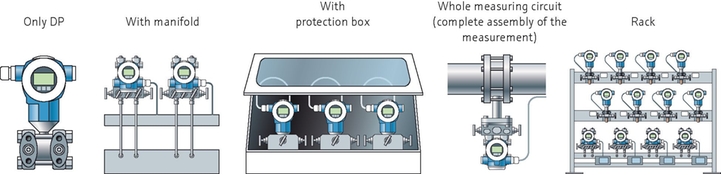

Our differential pressure (DP) flow competence team is at your disposal for any of your requests.

- We offer design calculations for the steam volume/mass

- We help to choose the best primary element, especially when it comes to permanent pressure loss

- We support and advice for correct installation, accessories, inclusion and commissioning

Automate pH measurements in flue gas desulfurization (FGD)

The pH value is very important for a properly functioning flue gas cleaning system – ultimately, it is used to regulate the feed rate of sorbents such as hydrated lime (Ca[OH]2) and limestone (CaCO3). Scrubber efficiency is highly dependent on the pH. It must be high enough that the sulfur dioxide (SO2) is reliably bonded. If it is too high, however, lime will be wasted, and the gypsum will be contaminated.

Our expertise in the field

Under these conditions, we recommend automating the cleaning and calibration of the pH sensors.

- Reduce maintenance costs and consumable material

- Remotely control your measuring points with Liquiline Control CDC90

- Avoid unplanned shutdowns, and reduce downtimes due to manual maintenance

Stop questioning your steam measurement

Measuring steam mass and energy requires correct compensation and sufficient inlet runs to obtain optimum results. Although steam is excluded from international custody transfer standards like OIML, there is a need for precise and reliable measurements.

Our expertise in the field

Our complete flow metering solutions for steam metering (compressed air, natural gas, etc.) is factory configured for energy metering or mass flow. It accurately measures steam across the entire range and allows suitable billing-relevant measuring points and custody transfer metering.

- Benefit from a completely pre-assembled, tested, customer-specific configured unit

- Avoid typical errors during planning, commissioning and operation

- Transparently measure energy and report on the efficiency of your plant

Save planning, procurement, mounting and maintenance costs

Displacers have been used in the past for level measurement in the condenser/hotwell, HP/LP feedwater heaters, flash and surge tanks. The output often varies due to accuracy, density variations, and installation differences.

Our expertise in the field

We provide guided wave radar (GWR) devices mounted in a bypass chamber that provide an optimum solution for such measuring tasks and offer numerous benefits.

- Fast and easy commissioning at site

- Pre-configured and tested bypass chamber solution that comes in one shipment

- Assured and certified quality

Increase the performance of your Waste-to-Energy (WtE) plant

The temperature at the boiler ceiling, superheaters and burnout zone of an WtE plant requires a high degree of measurement accuracy and control. Specific and innovative thermowell and protection tube materials are also required to resist exposure to aggressive fumes of combustion and high temperature oxidizing the environment.

Our expertise in the field

Endress+Hauser’s thermowells and protection tubes are outfitted with the right material for such applications.

- Longer lifetime of the measuring points under extreme conditions resulting in increased availability

- Reduced maintenance and thus lower life cycle costs

- Exchange of temperature measurements can be done in case of planned shutdowns

Benefits

Every innovation we create allows our customers to optimize their activities. We work constantly with our customers to ensure they are truly prepared to meet the requirements of the industry. Ultimately, it is the success of our customers which makes ours.

Key facts

>1 year

lifetime of our temperature sensors. By just using the right thermowell materials for temperature sensors, an E-f-W plant increases its plant uptime and efficiency.

Key facts

60+

years of experience in measurement instrumentation

Key facts

9 months

amortization time of the entire pH cleaning measuring point, if done with automated electrodes

How we can help

We focus on providing products, solutions and services to a diversified portfolio of power stations from the largest high-efficiency supercritical power plants and CCGT to cutting-edge renewable energy solution in hydroelectricity, geothermal, solar thermal, waste-to-energy and biomass. We strive for exemplary quality in our offering and look for partnerships with suppliers that apply the same principles of quality assurance. We deliver an extended scope of supply for measuring solutions:

- One delivery from a single, integrated supplier

- All components are qualified, tested and pre-assembled

- No time lost caused by mismatched parts or time-delayed delivery

- Minimized installation efforts

- On-site consultation, project planning and management, delivery, assembly, commissioning, documentation