In the traditional off-line quality control, samples are taken at various process stages and transported to a quality lab for analysis. It may take hours until the results are available, resulting in a delay, making result-based process control impossible. In a PAT-based approach the pharmaceutical manufacturing process and the analytical instrument, such as a spectrometer, acquire in-line measurement results in real time. This real-time data can improve both process control and product quality.

Key facts

> 1500

Kaiser Raman units installed worldwide

Increase process control and product quality with PAT

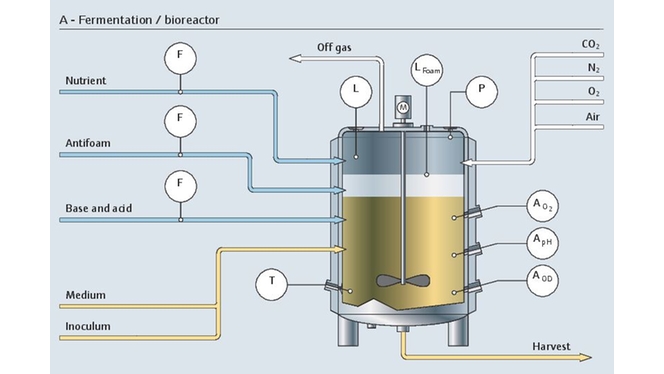

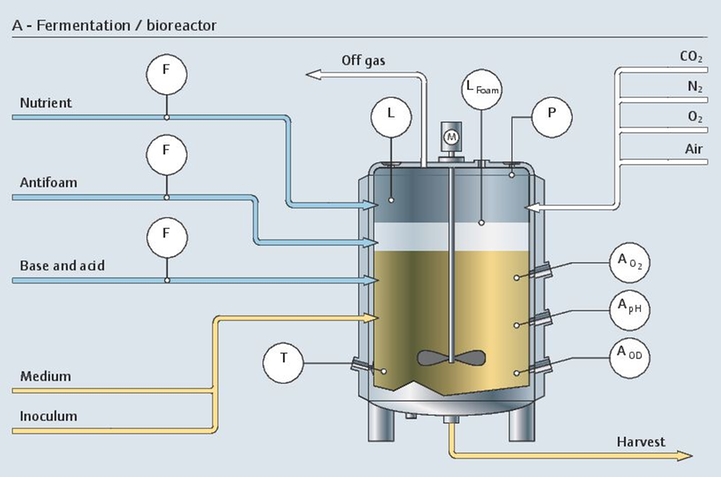

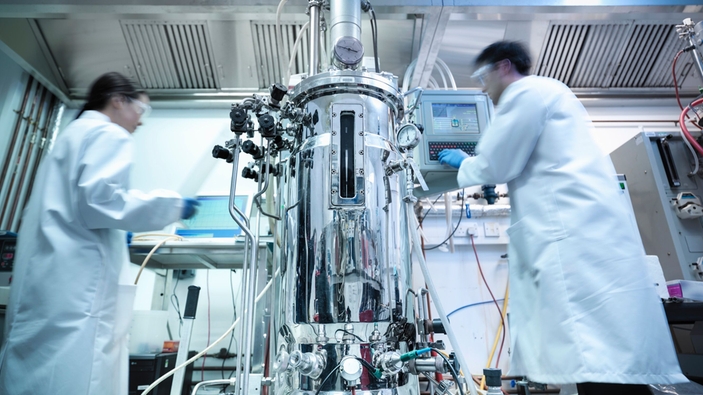

Optimized process control in bioreactors

In a bioreactor it is important to keep the dissolved oxygen and pH at an optimal level at all times. Cell density and metabolites should also be monitored for a better insight into the process. Concentration of metabolites is typically measured off-line with time consuming techniques and therefore require sampling with the associated risks.

Our expertise in the field

Raman spectroscopy is an ideal solution for fast and non-destructive measurement. Our Raman solutions can monitor several parameters simultaneously with one single probe installed directly in-line. The complete upstream package enables real-time and optimized control of the process leading to reduced time between batches, limited risk of contamination and increased yield.

- Raman Rxn analyzer, powered by Kaiser Raman technology, and reusable or single use bioprocess probe.

In-line glucose control

Glucose is the main energy source of cells during the upstream process. The concentration of glucose is a critical process parameter (CPP) because excessive glucose can lead to metabolic inefficiency and subsequent toxic lactate and glucose accumulation. Traditionally, a sample must be taken from the cultivation and analyzed in the lab to determine the amount of glucose that needs to be supplied to the bioreactor.

Our expertise in the field

Direct in-line monitoring of glucose concentration provides a better understanding and control of the fermentation or cell culture process. Continuous glucose measurements using Raman analyzers not only offer important bioprocess information for better process understanding but also bring huge potential for optimization. For example, with Raman-based glucose control in a mammalian cell bioprocess, titer increase of up to 85% has been realized.

- Kaiser Raman technology is easily integrated into bioreactor controllers, and is a proven PAT solution able to provide real-time process control and quality assurance

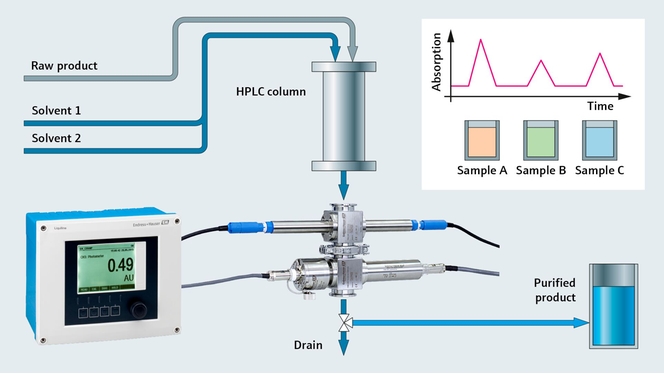

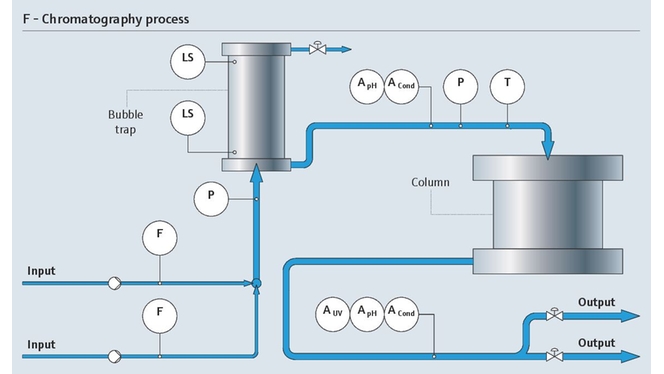

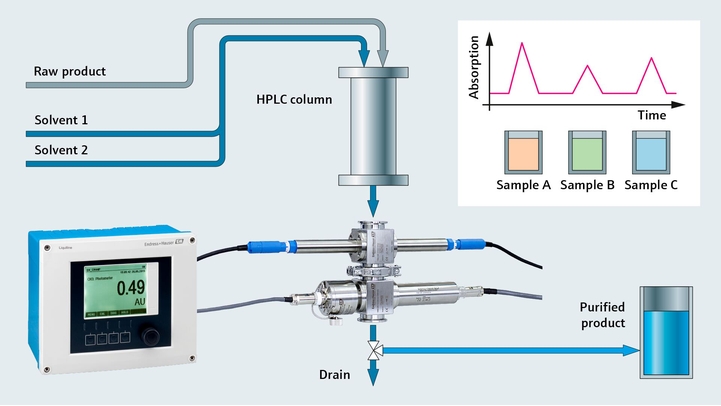

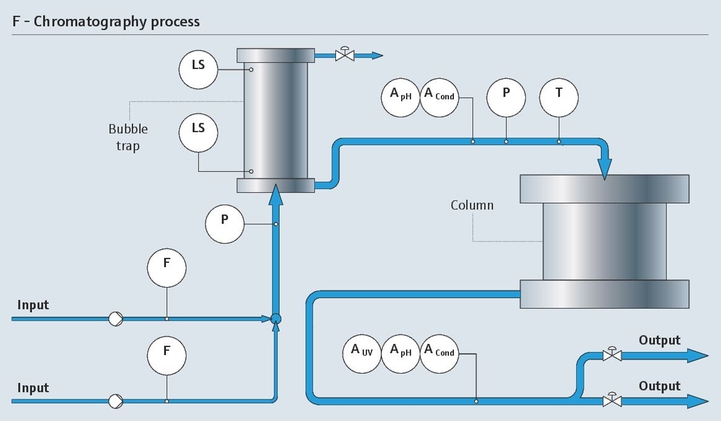

Protein monitoring in chromatography

As a pharmaceutical manufacturer, you strive for highest possible yield and purest product in your downstream process. Improving chromatography and the purification of your product mixture is a key aspect in achieving this goal. To achieve a maximum purification degree with minimum loss, you need precise and sensitive UV absorption with fast and reliable protein detection.

Our expertise in the field

With our UV absorption photometer, we bring the sensor and the measurement right into the process, by measuring the protein concentration in-line. For signal processing we use our well-known transmitter platform Liquiline. Using only one Liquiline CM44P transmitter, you can add pH and conductivity sensors, making it the perfect package for chromatography control.

- The OUSAF44 UV sensor monitors the concentration of your product in process liquids and is suitable for sterile processes (CIP/SIP)

- The low-volume flow cell OUA260 for the process photometers enables fast measurement and ensures optimum product yield. For pH and conductivity, the flow cell CYA680 is the right choice

- With the fully encapsulated Easycal system you get a safe and liquid-free on-line calibration of our UV sensors that is traceable to NIST

Benefits

With inline spectrometers a measurement frequency in the range of seconds can be achieved, thus enabling real-time advanced process control (APC) in pharmaceutical manufacturing. The move to process analytical technology (PAT) can help you develop processes that generate higher quality products and improve efficiency through increased automation, reduction in cycle times and uninterrupted batch/continuous processing.

Key facts

35

fermentation batches until ROI of a single channel Kaiser Raman Rxn system

Key facts

10x

lower maintenance costs of a Raman measurement compared to a chromatography system

Key facts

90%

less time spent calibrating one UV sensor with Easycal

How we can help

We can help you achieve advanced process control through in-line measurement of your critical quality parameters. You can get the analysis results in seconds instead of hours. From time consuming sample analysis to real-time monitoring of critical process parameters or critical quality attributes. With our optical technologies, such as Raman and UV spectroscopy, you can monitor and control the concentration or composition of your process media or final product in real time. Your benefits are:

- improved process control leading to optimized production and increased yield and quality

- elimination of contamination risks and time savings thanks to in-line process monitoring without the need for sampling

- complete packaged solutions for upstream and downstream process

- simplified scale-up with probes for all scales and technologies (i.e. glass, stainless steel, single-use plastic)